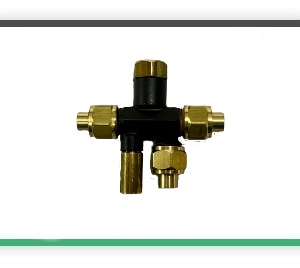

No.2 11oz/min. 5/32″ pipe

These are tested upto 120 PSI, and work from 30psi and lower, unto 120psi and higher made by David English

Fitting the injector

The steam feed, water and delivery tubes, should be copper to suit. The steam and delivery tubes should be kept as short as possible, and any bends must be large enough radius to ensure that the bore is not restricted. The feed check valve should have at least a 7/32″ ball. A fine gauze strainer should be fitted in the water tank to prevent any foreign matter fouling the injector cones

Operation

The injector will start at any preassure from 50Ibs to 100Ibs and often lower. The water valve should be opened first, the open the steam valve, if the water pours from the overflow in a fast steam, reduce the steam supply. Injectors will not work if water comes over with the steam. Therefore the steam must be taken from the highest part of the boiler.

Furring up

After much use, injector cones can fur up, to remove the fur you must release the cap and ball, then soak the injector in a solution of warm citric acid, this will dissolve the fur, then wash the injector in clean water reassemble